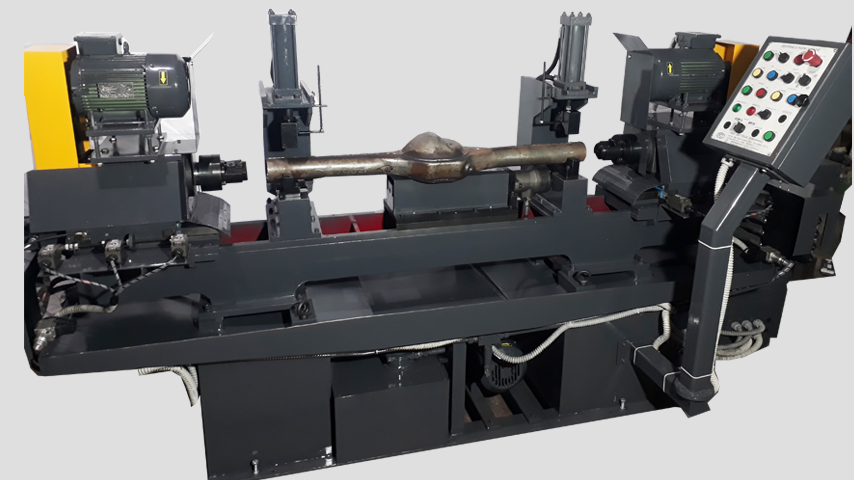

We are Manufacturer, Supplier of Differential Housing Boring Machines from Kolhapur, Maharashtra, India.

Boring and facing are machining operations commonly performed to ensure the proper dimensions and surface finish of a work piece.

Boring involves enlarging or finishing the inside diameter of a hole, while facing is the process of creating a smooth and flat surface on the end of a workpiece. For a differential housing, these operations may be required to ensure precision, proper fit, and functionality.

To achieve this, you would typically use a specialized Highly costed machine tool such as a horizontal boring machine or a vertical machining center with the appropriate tooling. To cut down maching cost & skill labour cost SPM MACHINE with dedicated operation are used. SPM MACHINE can be used where you have job assurity with high per month requirement for at least 2/3 years.

Here are the basic steps involved in the process :

Secure the differential housing in the machine, ensuring it is properly aligned and fixed in place. W.R.T Centre of differential housing adjust the both ends so that after facing both ends remains equi spaced from housing center

Choose Specialised boring and facing tools based on the specifications and requirements of the job.

Set the machine parameters such as cutting speed, feed rate, and depth of cut based on the material and dimensions of the differential housing.

Perform the boring operation to achieve the desired inside diameter, required tolerance and surface finish.

Once the boring is complete, the facing operation is performed on the end of the differential housing to create a flat and smooth surface. This is crucial for proper sealing and assembly.

After machining, perform quality checks to ensure that the dimensions and surface finish meet the specified requirements.