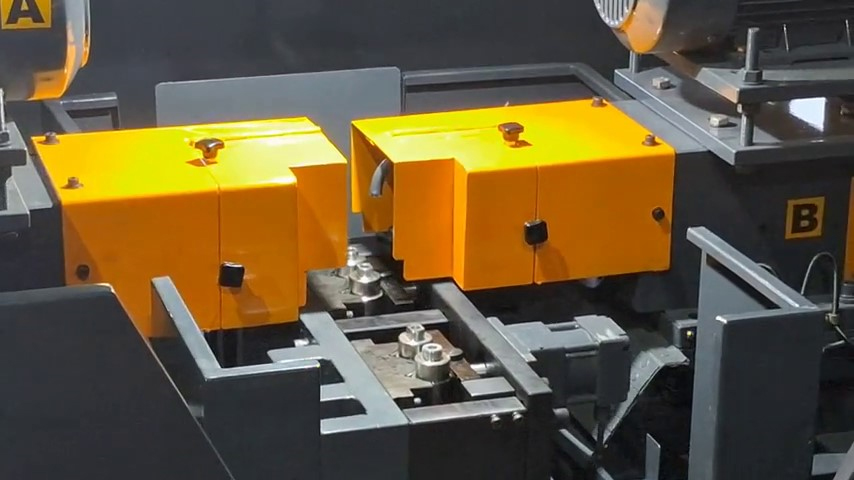

We are Manufacturer, Supplier of Washing Machine Motor Shaft Milling SPM from Kolhapur, Maharashtra, India.

Washing Machine Motor Shaft Milling SPM : When it comes to high-volume production, Special Purpose Machines (SPM) are often employed for specific tasks, such as milling motor shafts for washing machines. SPMs are designed to perform a particular operation efficiently and with a high degree of automation. Here's a general guide on how you might approach milling a motor shaft for a washing machine using a Special Purpose Machine:

Materials and Tools:- Washing machine motor shaft blanks

- SPM Machine for motor shaft milling

- Specially designed milling cutters for the SPM

- Cooling system (if applicable)

- Measuring tools (calipers, micrometers)

- Safety equipment (safety glasses, gloves)

Set up the washing machine motor shaft blanks on the SPM machine. Ensure proper alignment and secure clamping for stability during milling.

Choose or design milling cutters that are specifically tailored for the motor shaft milling operation. Install these cutters in the SPM machine according to the machine's specifications.

Program the SPM machine with the necessary parameters, including cutting speeds, feed rates, and the specific milling path for the motor shaft. This may involve CNC programming or other control systems depending on the complexity of the SPM.

If your SPM machine is equipped with a coolant system, ensure that it is functioning properly. The coolant helps in lubricating and cooling the milling cutters during the operation, improving efficiency and tool life.

Start the automated milling operation on the SPM machine. The machine will follow the programmed path to mill the motor shafts. This can include rough milling passes followed by finishing passes for precision.

Incorporate in-process inspection points if possible to ensure that the milling operation is producing motor shafts within the specified tolerances. Automated inspection systems can be integrated into SPMs for quality control.

Periodically check the dimensions of the machined motor shafts using measuring tools. Adjust the SPM parameters if necessary to maintain accuracy.

Implement deburring and cleaning processes as part of the SPM system or as a subsequent step to remove any sharp edges or residual material from the machined motor shafts.

Conduct thorough quality checks on a sample basis to ensure that the machined motor shafts meet the required standards for dimensions, surface finish, and overall quality.

Continuously monitor the SPM machine's performance to ensure its efficiency and address any issues promptly. Regular maintenance is essential to keep the machine in optimal working condition. Always adhere to safety guidelines, wear appropriate personal protective equipment, and refer to the manufacturer's guidelines for both the SPM machine and milling cutters. Additionally, consider consulting with experienced engineers or technicians familiar with the specific SPM used in your manufacturing process.